Our Capabilities

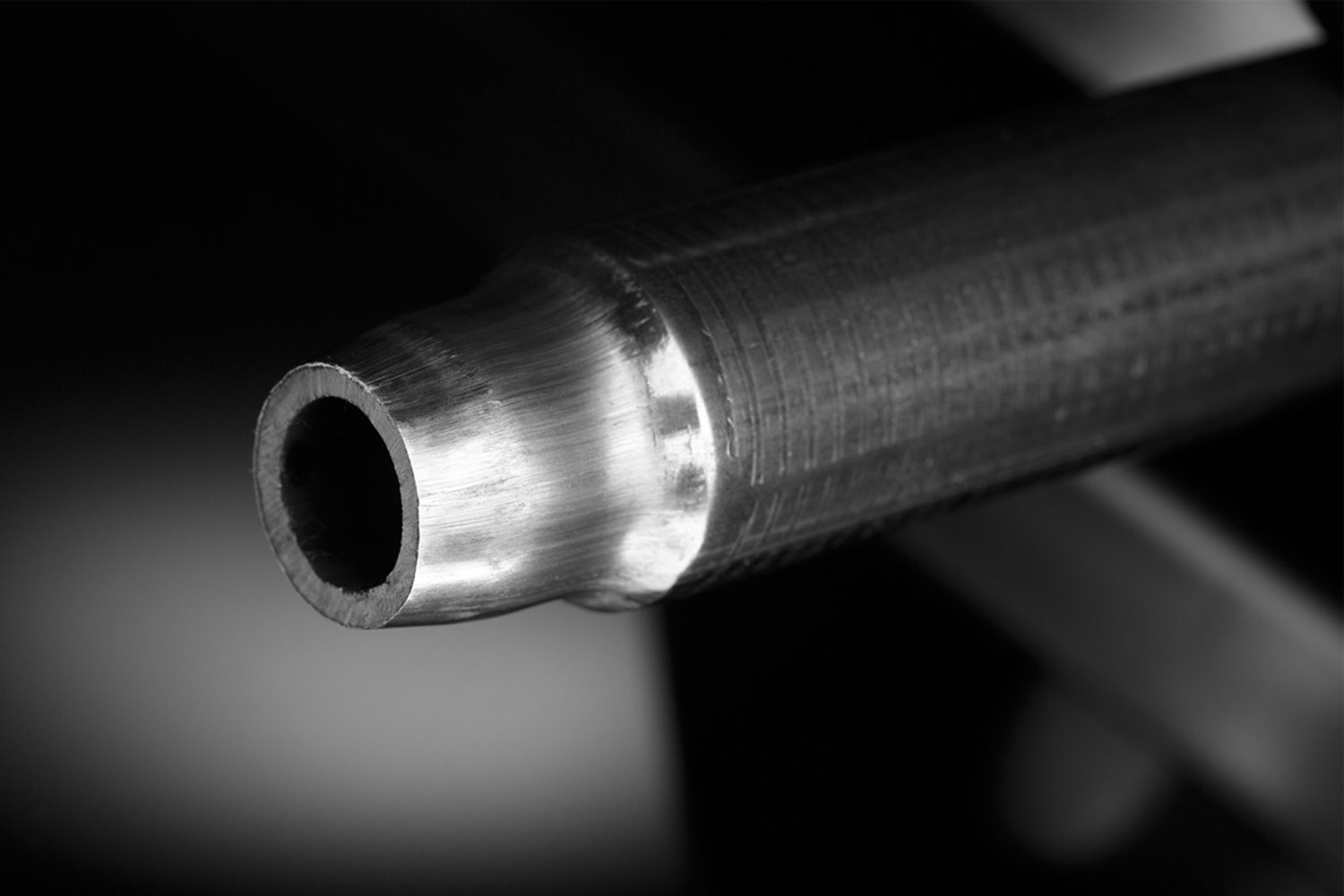

At L&P Aerospace, we specialize in creating complex tube and duct assemblies using high-performance materials capable of withstanding extreme pressure, temperature, and chemical interaction.

Materials

We use strong, durable stainless steel for everything from medical applications to aerospace components. Nickel alloys feature a high temperature resistance and the ability to hold up under corrosive chemicals, so this material is used in the hottest parts of engine turbines and in settings with heavy chemical usage. Our titanium and titanium alloys are our strongest materials, with a high strength-to-weight ratio that makes them a great choice for high-pressure applications, such as aerospace pressurization.

These materials are formed and drawn into tubes and ducts in our many facilities, using our custom-developed machinery and welding techniques.

Processes:

Once we have our tubes or ducts formed, we can then customize them to fit our customers’ exact specifications. Our expert staff and state-of-the-art equipment allow us to ensure the precision of all our custom components.

At our many facilities, our capabilities include:

- Tube redrawing

- Bead-reducing and plannishing

- Cold-drawing

- Cold-pilgering

- Welding of thin-wall materials

- Welding of heavy-wall materials

- Heat treating

- NDT – dye penetrant

- NDT – Eddy current

- NDT – ultrasonic

- NDT – X-ray, conventional, and digital

- Endoscope

- Cleaning

- Degreasing

- Straightening

- Polishing, grinding

- Sand-blasting

- Passivation, pickling, and acid etching

- Cutting

- Forming

- Marking and packaging

- Lab testing (tensile, roughness, pressure, corrosion, macro/micrography, grain size, hardness, flattening, flaring, hydrogen content, CSR)

- CNC 3D measuring

Finished Goods

After our materials have gone through the necessary processes, we’re left with high-performance finished goods that are ready to be incorporated into assemblies for our customers.

These finished goods include:

- Seamless tubing

- Welded tubing

- Heavy-wall tubing

- Precision tubing

- Drawn tubing

- Large-diameter tubing

- Needle tubes

- Thin-wall tubing

- Sleeves

- Serpentines